In today’s highly competitive textile industry, quality isn’t just a selling point—it’s the standard. Consumers expect their garments to be comfortable, visually appealing, and durable, with a premium finish that elevates everyday wear. Amidst this demand for better fabric feel and finish, bio-polishing has emerged as a game-changing technique, and at the heart of it lies a humble yet powerful enzyme: cellulase.

This naturally occurring enzyme, widely used in textile processing, has revolutionised the finishing process of knitwear, especially those made from cellulosic fibres like cotton and viscose. Let’s take a closer look at how cellulase enzymes are driving a sustainable transformation in the way we finish knitwear—delivering softness, sheen, and superior quality, without compromising on the planet’s well-being.

What is Bio-polishing?

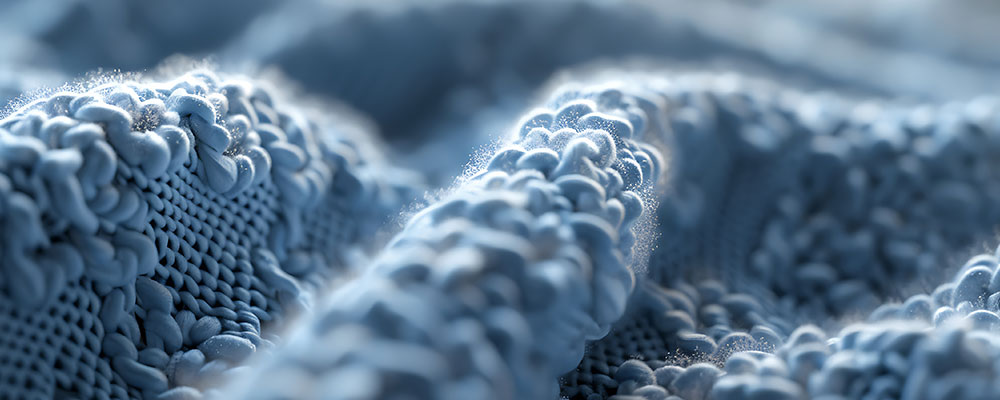

Bio-polishing, also known as enzymatic surface modification, is a textile finishing process that uses enzymes to remove protruding fibres and fuzz from the surface of fabrics. This results in a smoother surface, brighter colours, and reduced pilling—an issue notoriously common in cotton knitwear.

Traditionally, mechanical methods or harsh chemical treatments were employed to achieve similar effects. However, these often led to compromised fabric strength, environmental pollution, and increased operational costs. Bio-polishing, on the other hand, provides a clean, eco-friendly, and efficient alternative—one that aligns seamlessly with the modern textile industry’s sustainability goals.

Cellulase: The Enzymatic Workhorse

Cellulase is a class of enzymes that catalyse the breakdown of cellulose, the main structural component in plant-based fibres. These enzymes hydrolyse the β-1,4-glycosidic linkages in cellulose, resulting in the formation of glucose and other soluble sugars. In textile bio-polishing, the action of cellulase is more controlled and surface-level—it targets the fine, protruding microfibrils on the yarn surface without degrading the core fibre.

There are several types of cellulase used in textile applications, including endoglucanases, exoglucanases, and β-glucosidases. Of these, neutral and acid cellulases are particularly prominent in bio-polishing, with acid cellulases being widely preferred for cotton processing.

The targeted action of cellulase ensures minimal damage to the fabric’s integrity while enhancing its tactile and visual properties. This makes it the perfect choice for delicate knitwear, where maintaining softness and strength is critical.

Benefits of Using Cellulase in Knitwear Bio-polishing

- Enhanced Fabric Smoothness

Cellulase helps remove surface fuzz and loose fibres, resulting in a noticeably smoother fabric. This significantly enhances the hand feel, making knitwear soft, silky, and pleasant against the skin. - Improved Colour Brightness and Lustre

The removal of microfibrils allows dyes to penetrate more evenly and reflect light more effectively, leading to brighter, deeper, and longer-lasting colours. This is especially valuable in fashion knitwear, where visual appeal is paramount. - Pilling Resistance

Pilling is a common issue in knitwear that diminishes both the appearance and durability of garments. Cellulase treatment reduces the potential for pills to form by eliminating the fibres that would otherwise entangle and create unsightly fabric balls. - Increased Fabric Durability

Unlike abrasive methods that wear down the fabric, enzymatic treatment is gentle and controlled. This helps preserve the fabric’s core structure, enhancing its life span and wearability. - Eco-Friendly Process

Bio-polishing with cellulase is carried out under mild conditions—moderate temperatures and neutral to slightly acidic pH levels. It consumes less water and energy compared to traditional methods and does not produce harmful effluents, making it a truly green solution. - Operational Efficiency

With proper process control, cellulase treatment can be integrated seamlessly into existing wet processing lines, often allowing for simultaneous desizing or scouring. This reduces processing time and costs, boosting overall plant efficiency.

Application Considerations and Process Optimisation

To achieve the best results with cellulase in bio-polishing, several factors must be carefully controlled:

- pH and Temperature: Most cellulases operate optimally between pH 4.5 and 5.5 and at temperatures between 45–55°C. Maintaining these parameters is essential for consistent enzyme activity.

- Dosage: The enzyme concentration should be adjusted based on fabric weight, composition, and the desired degree of polishing. Overdosing can lead to unwanted fabric strength loss, while under-dosing may yield suboptimal results.

- Time: Longer treatment times typically result in more pronounced effects, but should be balanced to avoid fabric damage.

- Mechanical Agitation: Controlled agitation helps ensure even treatment by exposing all parts of the fabric to enzymatic action.

Additionally, modern enzyme formulations are often designed to be highly stable and compatible with various auxiliaries, allowing for multi-functional treatments within a single bath. This is particularly useful in large-scale textile mills where productivity and consistency are crucial.

Towards a Sustainable Textile Future

With global fashion brands pushing for greater transparency and sustainability in their supply chains, adopting green technologies like cellulase-based bio-polishing has moved from being optional to essential. Not only does it enable manufacturers to meet stringent environmental norms, but it also helps them deliver higher-quality products that align with consumer expectations for comfort and durability.

Moreover, enzymatic treatments open the door for circular fashion practices. Fabrics that have been treated with eco-friendly processes are easier to recycle and less likely to contribute to microplastic pollution, setting the stage for a more responsible and regenerative textile industry.

Conclusion

In a world where textile manufacturers must continuously balance quality, cost, and environmental responsibility, cellulase in bio-polishing offers a solution that delivers on all fronts. From enhancing the touch and visual appeal of knitwear to offering resistance to pilling and contributing to longer garment lifecycles, the benefits are both tangible and impactful. This natural, enzyme-driven process doesn’t just finish fabric—it refines it, giving it a premium feel without harming the planet.

At Biolaxi Enzymes, we understand the critical role of enzyme innovation in driving textile excellence. With over 14 years of scientific expertise and a commitment to quality, we deliver high-performance textile enzymes that cater to the evolving needs of modern mills. Our cellulase formulations are engineered for precision, sustainability, and efficiency—helping our partners craft better fabrics, naturally.